2021.05.13 Hyundai Motor Group

With the emergence of hydrogen-electric vehicles and the development of fuel cells that generate electricity using hydrogen as fuel, we have taken a step closer to an eco-friendly hydrogen society. The technical foundation for using hydrogen as the main energy source was laid. So, what do we need in order to use hydrogen energy everywhere in our lives? It is necessary to build an infrastructure that will increase access to hydrogen energy.

The Hyundai Motor Group, which produced the world's first hydrogen-electric vehicle, is actively investing in hydrogen infrastructure as well as developing hydrogen-electric vehicles and fuel cells and building mass production systems. Let's take a look at the activities of Hyundai Motor Group, which is striving to build infrastructure in various fields from production to transportation and supply to realize a hydrogen society.

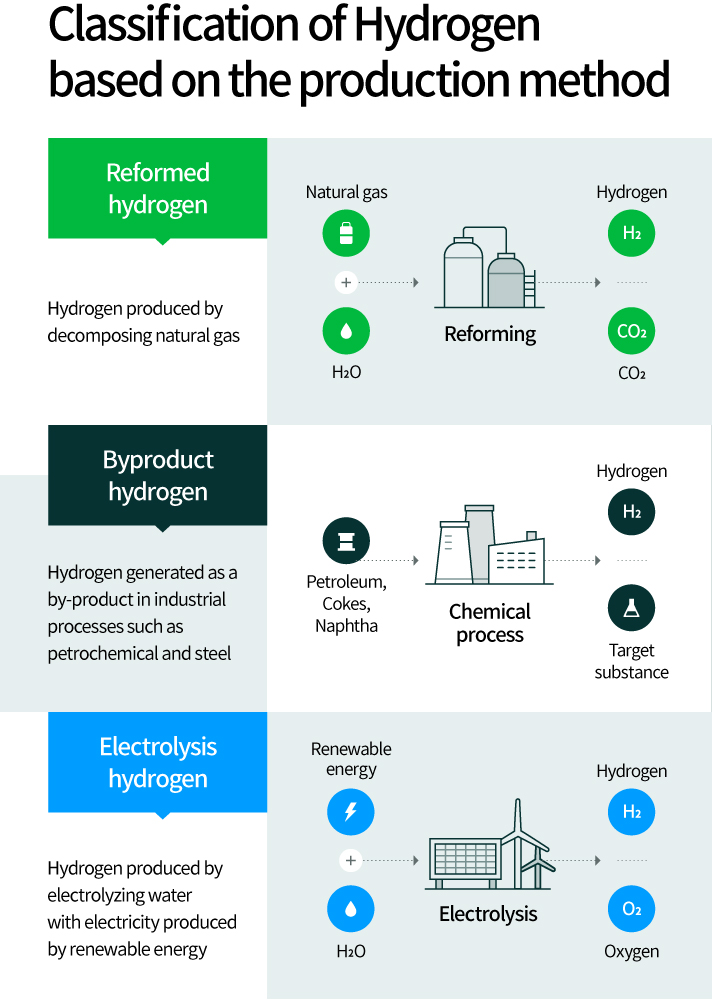

One of the most important tasks in a hydrogen society powered by hydrogen energy is supplying hydrogen

without a shortage. As is commonly known, hydrogen is the most common material in the universe, but pure

hydrogen, which can be used as energy, does not exist in its natural state on Earth. In other words, in

order to utilize hydrogen energy, it is necessary to extract pure hydrogen from organic compounds such

as water, gasoline, natural gas, propane, and methanol.

There are many different ways of producing hydrogen. Among them, the most economical way to produce

hydrogen is to extract hydrogen from natural gas. In order to quickly build a hydrogen infrastructure,

it is necessary to be economically competitive and to do so, hydrogen production facilities through

natural gas reforming must be preemptively equipped.

Hyundai Rotem built a hydrogen reformer manufacturing plant at the Uiwang Research Center last year. A

hydrogen reformer is a device that extracts hydrogen from natural gas and is an essential device for

smooth supply of hydrogen in the early stages of entering the hydrogen society. The plant built by

Hyundai Rotem has the ability to produce 20 hydrogen reformers per year. The amount of hydrogen produced

by 20 hydrogen reformers is about 4,700 tons per year, which is a scale that can fill up 850,000

hydrogen-electric vehicles (based on Nexo).

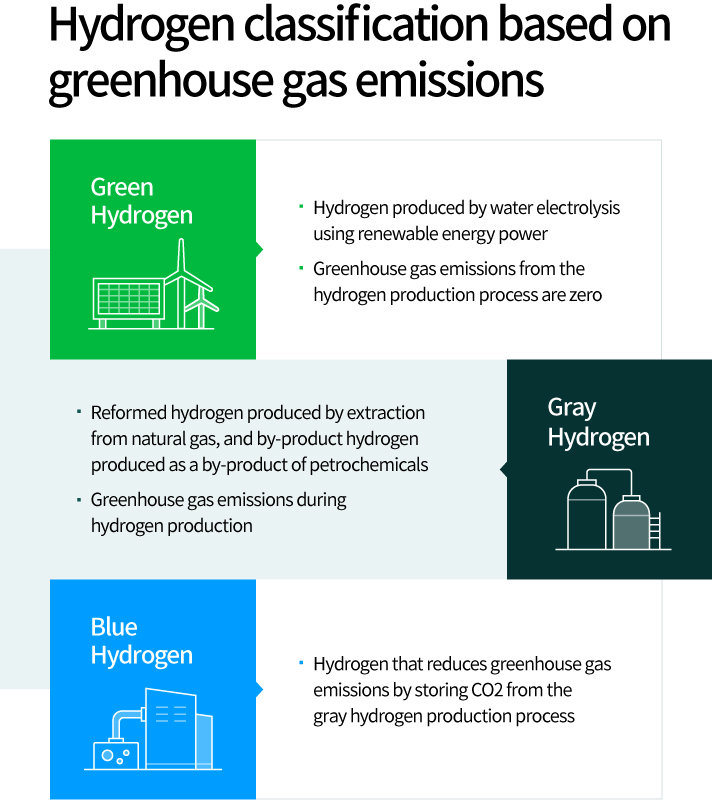

Hydrogen is divided into three types depending on whether or not greenhouse gases are generated during

the production process. Hydrogen extracted from fossil fuels such as natural gas is called 'gray

hydrogen'. Hydrogen produced by filtering out carbon dioxide generated in the hydrogen production

process to suppress greenhouse gas emissions is called 'blue hydrogen'. Hydrogen produced by

electrolyzing water by receiving electric energy from renewable energy is classified as 'green

hydrogen'. In order to quickly build a hydrogen production infrastructure, it is important to supply

reformed hydrogen production facilities with excellent economic efficiency, but from a long-term

perspective, it is also important to build eco-friendly hydrogen production facilities, which are the

main purpose of using hydrogen energy.

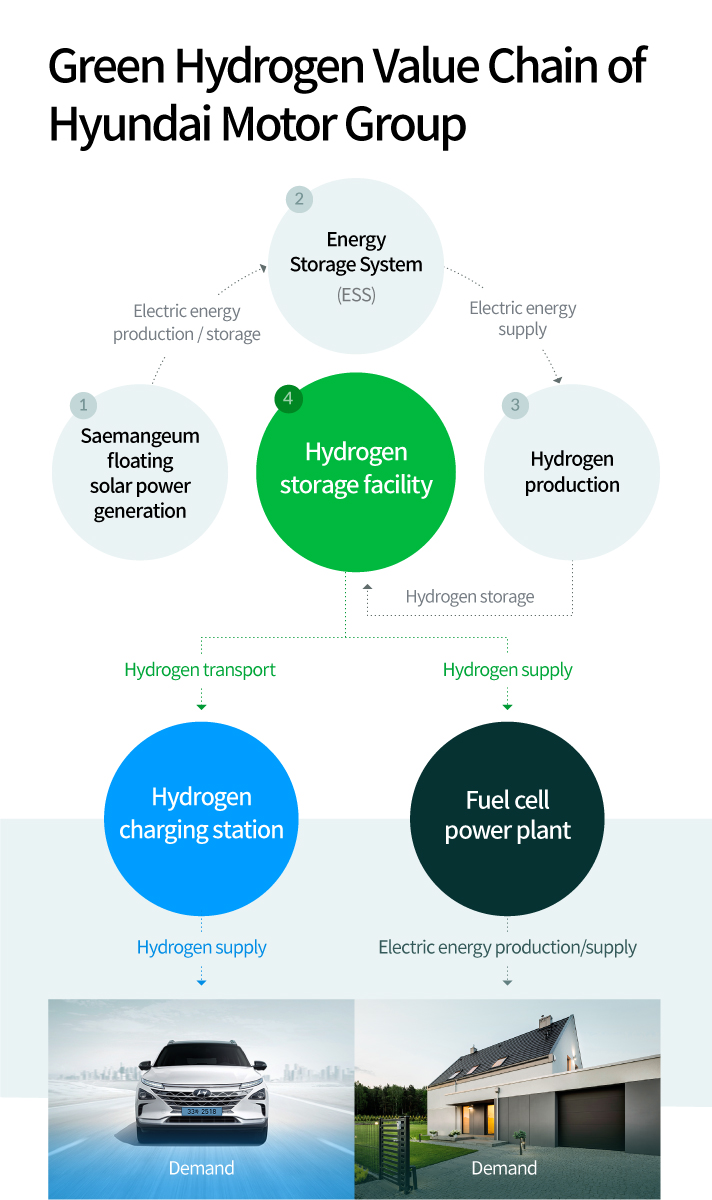

The Hyundai Motor Group continues its efforts to produce not only economical hydrogen, but also green

hydrogen that does not emit GHG emissions. An activity that demonstrates this well is a joint research

for the commercialization of a green hydrogen value chain. This research was conducted in collaboration

with 8 organizations and companies including Hyundai Motor Company, Hyundai Engineering, Hyundai Motor

Securities, Saemangeum Development Agency, Saemangeum Development Corporation, LG Electronics, Korea

Western Power, and Hydrogen Energen. This is a project to verify the feasibility of a green hydrogen

business that links renewable energy and hydrogen utilization such as solar power, energy storage

devices, water electrolysis facilities, and fuel cells. The goal of this project is to build power

generation facilities such as solar modules and energy storage systems in the Saemangeum area, and to

produce hydrogen from the generated electricity and supply it to hydrogen consumers or send it to fuel

cells to build a value chain that supplies electric energy to the places where it is needed. In

particular, the 'polymer electrolyte fuel cell (PEMFC)' power generation system scheduled to be supplied

by Hyundai Motor Company has the advantage of being able to start and stop immediately and to change the

output quickly. It is expected to contribute to the diffusion of renewable energy and hydrogen energy in

the future.

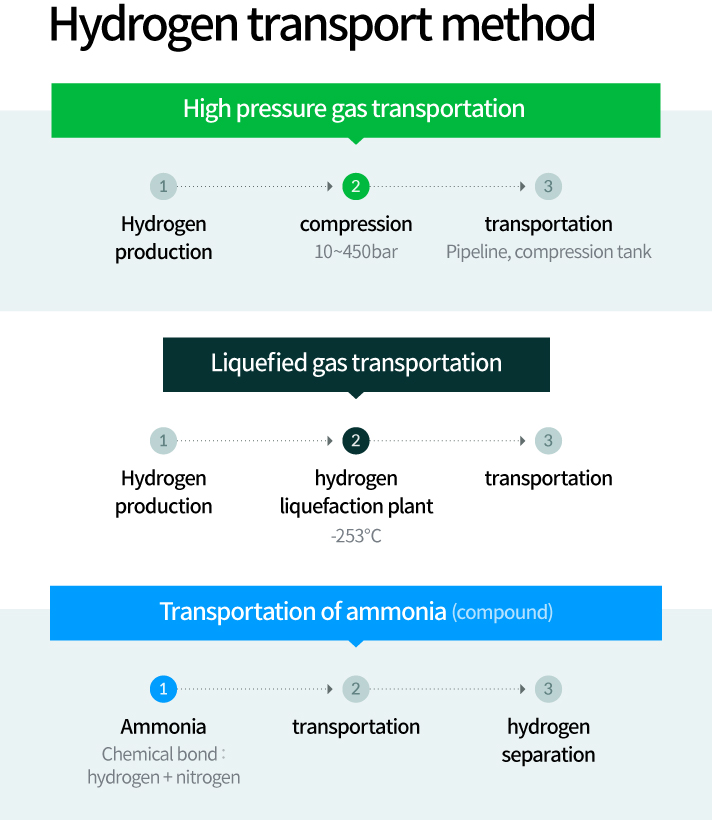

As interest in hydrogen society grows around the world, developed countries pay attention not only to the hydrogen production facilities but also to the hydrogen transportation infrastructure. The hydrogen transport technology is not only essential to safely transport the hydrogen produced, but it is also very important in that it can lower the price of hydrogen supply by optimizing the supply network. In the case of Korea, while leading the global industry in the field of hydrogen utilization such as hydrogen-electric vehicles and fuel cell power generation, it is still in the development stage in the areas of production, transportation, and supply.

Accordingly, Hyundai Glovis has been building a systematic hydrogen supply network from the first half of this year in cooperation with Hynet (Hydrogen Energy Network Co., Ltd.), Hyundai Steel, Hyundai Motors, Korea Gas Corporation, and SPG. This is a business that supplies hydrogen produced at Hyundai Steelworks in Dangjin to hydrogen charging stations located in the metropolitan and Chungcheong areas, and Hyundai Glovis plans to introduce a tube trailer, a special transport vehicle for hydrogen. The vehicle can carry up to 340 kg of hydrogen at a time.

Currently, domestic hydrogen transportation does not have an integrated system, so information at each stage such as hydrogen production, transportation, and consumption is not linked, so hydrogen supply is not smooth, which incurs unnecessary transportation costs. Hyundai Glovis plans to accelerate the creation of a hydrogen ecosystem by using its own 'Hydrogen Supply Chain Management Optimization Platform' to improve the efficiency of the domestic hydrogen transportation market.

In order to establish a global hydrogen supply network as well as to establish a domestic hydrogen supply network, Hyundai Glovis cooperated with a domestic shipbuilder to develop a large-sized liquefied hydrogen carrier. In order to transport large amounts of hydrogen to ships along ocean routes, a liquefaction process that reduces volume and increases stability is essential. Liquefied hydrogen has a volume of 1/800 compared to hydrogen gas, making storage and transportation much easier and more economical. By participating as a shipping company in the joint development of hydrogen carriers, Hyundai Glovis directly verifies the economics and safety of hydrogen transportation, accumulates know-how, and plans to secure competitiveness in hydrogen maritime transportation in the future.

The hydrogen charging station, which supplies hydrogen to hydrogen-electric vehicles, is the core of the

hydrogen infrastructure in which hydrogen storage and transportation technology is abbreviated.

Considering that hydrogen storage technology and hydrogen transport networks are essential, it can be

said that countries with more hydrogen charging stations are closer to hydrogen society. Since it is a

facility where consumers directly use hydrogen energy, it is also an important infrastructure that will

increase the affinity for hydrogen energy and change the perception of hydrogen.

Hyundai Motor, which is the first in the world to mass-produce hydrogen-electric vehicles, and is leading the development and distribution of various hydrogen mobility such as hydrogen buses and hydrogen trucks, is actively conducting activities to build hydrogen charging stations in city centers and highways to build a hydrogen ecosystem as well as popularize hydrogen-electric vehicles. 'H Station', a hydrogen charging station built by Hyundai Motor Company, opened in the Anseong service area in April 2019, and started at 9 locations nationwide, including Yeoju, Haman, Hanam, Yeouido, Gangdong, Busan, Incheon, and Wanju (charging stations specially built for hydrogen commercial vehicle). Hyundai Motor Company is also supporting the supply of hydrogen charging stations by investing in Hynet, which is taking the lead in building hydrogen charging stations, and aims to build 100 hydrogen charging stations by 2022 in cooperation with the government.

As such, Hyundai Motor Group is making efforts to establish a stable hydrogen infrastructure from hydrogen production to transportation and supply, as well as hydrogen mobility. This is because building a hydrogen infrastructure is a prerequisite for entering a hydrogen society. This is why countries around the world, including Korea, as well as the United States, Europe, Japan, and China, who want to take the lead in hydrogen society, are accelerating the construction of hydrogen infrastructure. Let's hope for a hydrogen society, a truly eco-friendly world without carbon emissions.